A Guide to Rocket Engines: From Solid to Plasma and Beyond

Explore how rockets generate thrust, from chemical engines that lift off the pad to electric and nuclear systems driving long-duration spaceflight.

At its core, a rocket is nothing more than a vehicle that throws mass backwards in order to push itself forwards. Every rocket engine, no matter how advanced, follows this same principle. The thrust it produces depends on two things: how much exhaust it can push out (Mass Flow Rate), and how fast that exhaust is moving when it leaves the rocket (Exhaust Velocity).

In chemical rockets, thrust can be increased in two fundamental ways: by burning more fuel per second (kg/s), which raises the mass flow rate, or by ejecting that fuel’s exhaust at a higher speed (m/s), which raises the exhaust velocity. The first method is relatively straightforward and can be accomplished just by adding more engines. The second is far more challenging, as exhaust velocity is constrained by the chemistry of the fuel and the physics of the nozzle. However advanced the engineering, these limits are far harder to overcome.

Chemical Propulsion

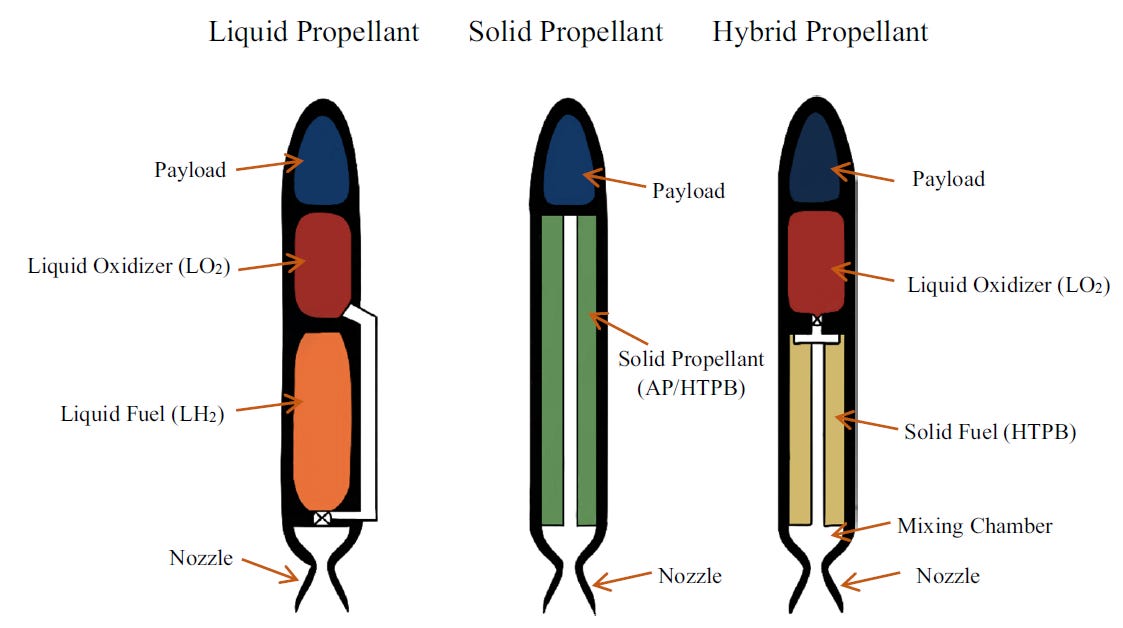

Rockets carry both fuel and oxidizer on board, a self-contained design that allows them to function in the vacuum of space, far beyond the reach of jet engines, which rely on external oxygen. These two components are then mixed and ignited inside the combustion chamber, producing extremely hot, high-pressure gas that is expelled to generate thrust.

To convert this heat into motion, the engine relies on a nozzle. The gas molecules inside the combustion chamber move chaotically in all directions, producing pressure but little thrust. The nozzle redirects this random thermal energy into a focused stream of kinetic energy, turning heat into thrust.

Solid Fuel Rocket Engines

The oldest form of rocket propulsion is the solid-fuel rocket. In these systems, fuel and oxidizer are premixed into a rigid block known as a propellant grain. Once ignited, the grain burns from its exposed surfaces until it is completely consumed. Solid fuel rockets are widely used in both space launch vehicles and military applications, valued for their long storage life, ability to launch on short notice, and capacity to deliver immense thrust without the complex plumbing and fueling systems required by liquid-fuel engines.

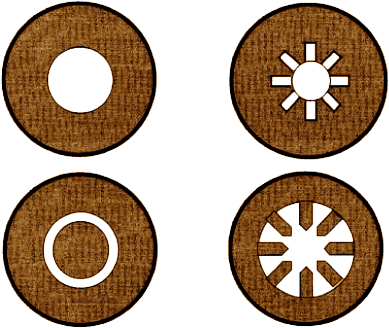

The shape of the propellant grain is critical because it determines how thrust changes during the burn. If the burning surface area grows larger as the grain depletes, thrust increases in what is called a progressive burn. If the surface area shrinks, thrust decreases in a regressive burn. Some designs, such as the Space Shuttle’s star-shaped grain, keep the burning surface constant, producing a neutral burn that maintains a nearly steady thrust throughout the ascent.

Despite their strengths, solid fuel rockets have some limitations. Once ignited, they cannot be throttled, shut down, or restarted; the burn continues until the propellant is fully consumed. Their exhaust velocities, typically between 2,500 and 3,500 meters per second, are lower than that of liquid-fueled engines. For this reason, solid-fuel rockets are rarely used as the sole propulsion system for orbital launches today. Instead, they excel as boosters that provide the brute force needed to lift heavy vehicles off the pad, and in military applications such as air-to-air, surface-to-air, and intercontinental ballistic missiles, where rapid response, reliability, and long storage life are essential.

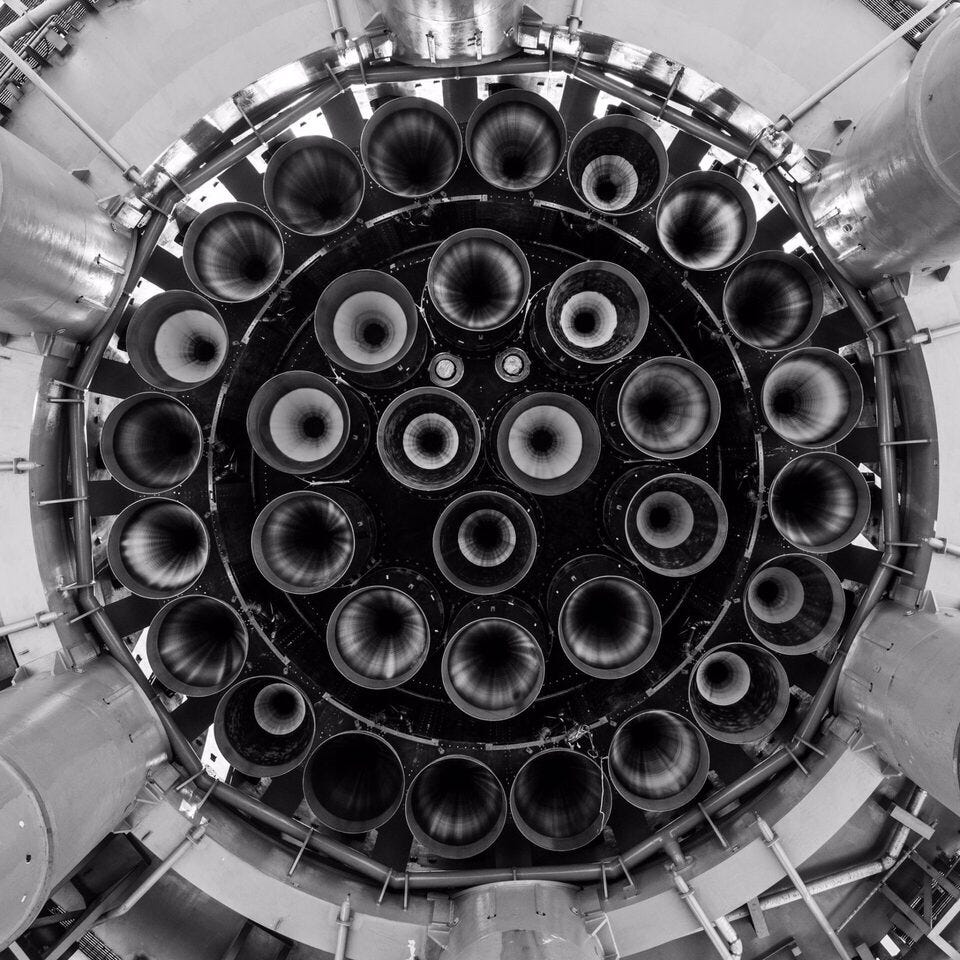

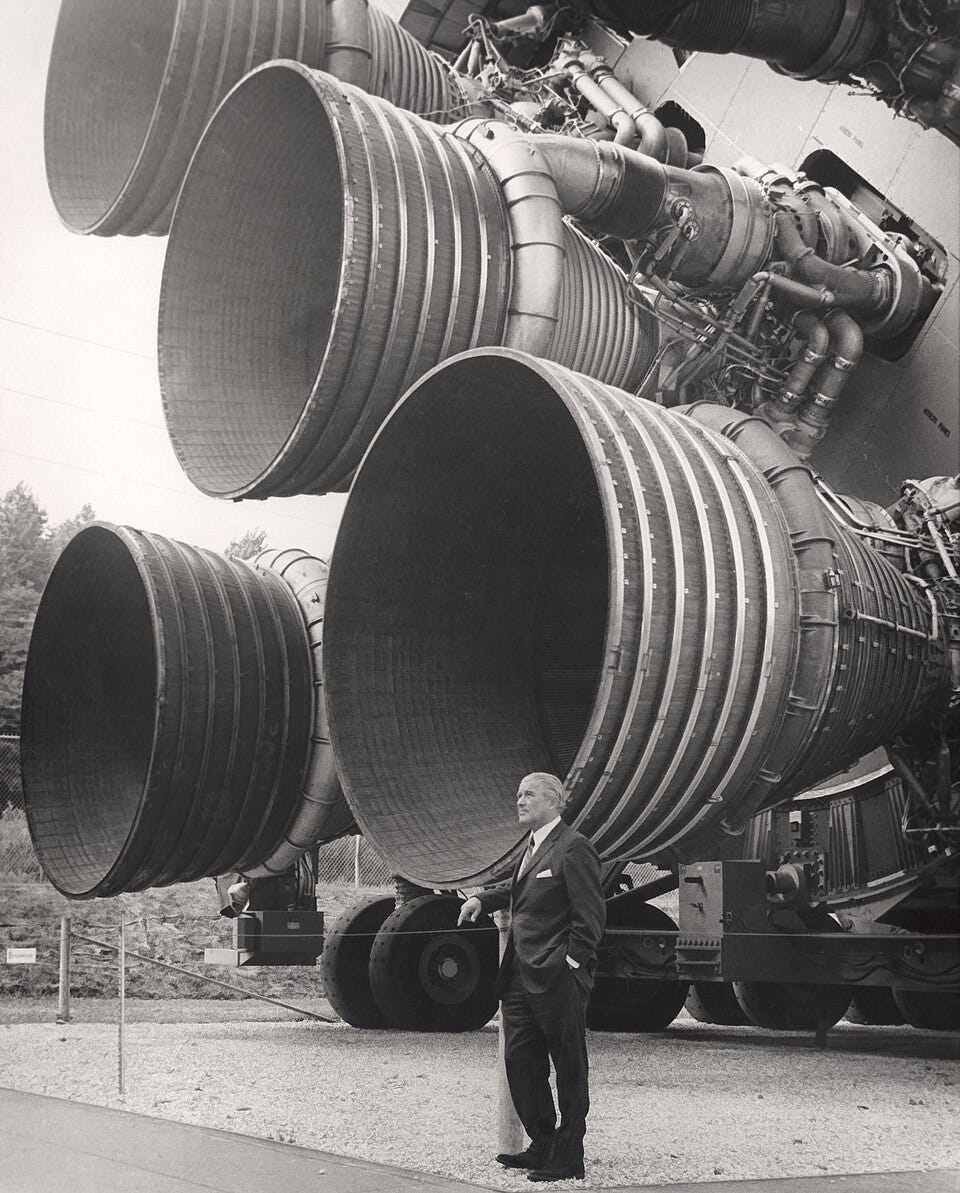

Liquid Fuel Rocket Engines

In liquid-propellant engines, the fuel and the oxidizer are stored in separate tanks and pumped into a combustion chamber, where they mix and ignite. This design provides much greater control, allowing thrust to be adjusted during flight, engines to be shut down and restarted, and precise orbital maneuvers to be carried out long after launch.

There are different fuel–oxidizer combinations, each suited to specific role. A pairing called hydrolox (liquid hydrogen and liquid oxygen) offer very high efficiency but demand cryogenic storage, kerolox (densified kerosene and liquid oxygen) are easier to handle and provide strong lift-off power. Liquid methane is emerging as a cleaner, cost-effective alternative, and hypergolic propellants, though toxic and less efficient, remain vital for orbital maneuvering because they ignite instantly.

Liquid engines typically achieve exhaust velocities between 3,000 and 4,800 meters per second. Yet the power of liquid propulsion comes at a cost. Cryogenic fuels must be kept at extremely low temperatures, which requires heavy insulation and careful handling. Propellants can slosh inside their tanks, destabilizing the rocket during flight unless carefully managed. The plumbing itself is a dense network of pumps, valves, and pipes, where a single failure can doom a mission. Moreover, many liquid propellants and oxidizers are hazardous to humans: some are cryogenic and can cause severe burns on contact, while others, such as hydrazine, are highly toxic. Even small leaks can be dangerous or fatal, which makes fueling and storage operations risky and complex. In short, liquid propellants are harder to manage than solid ones, but they remain vastly more capable.

Hybrid Rocket Engines

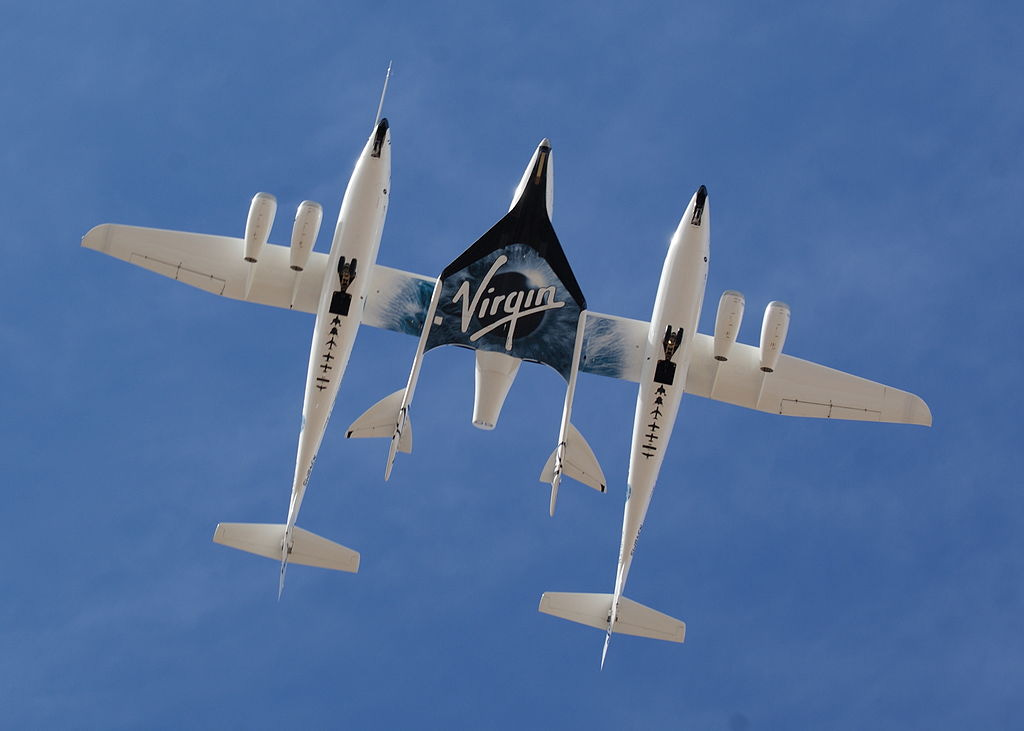

Hybrids engines typically pair a solid fuel with a liquid oxidizer. The solid grain provides long-term storage stability, while the liquid oxidizer allows some throttle control, since the engine can be shut down or restarted by opening and closing a valve, something solid-only engines cannot do. Hybrids are also relatively inexpensive and straightforward to build, which has made them appealing to smaller rocket companies.

In theory, hybrids promise the best of both worlds: safer than pure liquids and more flexible than pure solids. In practice, however, they often deliver the drawbacks of both. Combustion can be uneven, hot gases may blow back into the oxidizer tank, and the fuel-to-oxidizer ratio is difficult to manage because the grain geometry changes as it burns. Their exhaust velocities, typically between 1,800 and 2,400 meters per second, are also lower than those of most solid or liquid engines, limiting their efficiency.

Beyond Chemistry: Advanced Propulsion

Chemical rockets are immensely powerful, but their performance is ultimately constrained by chemistry. The reaction energy released when fuel and oxidizer combine sets a hard ceiling on exhaust velocity, and no amount of engineering can push it much higher. To move beyond those limits, alternative approaches to propellant have been explored an developed, including electric ion thrusters, nuclear thermal rockets, and light-based systems such as solar sails and laser-driven propulsion.

Electric Propulsion

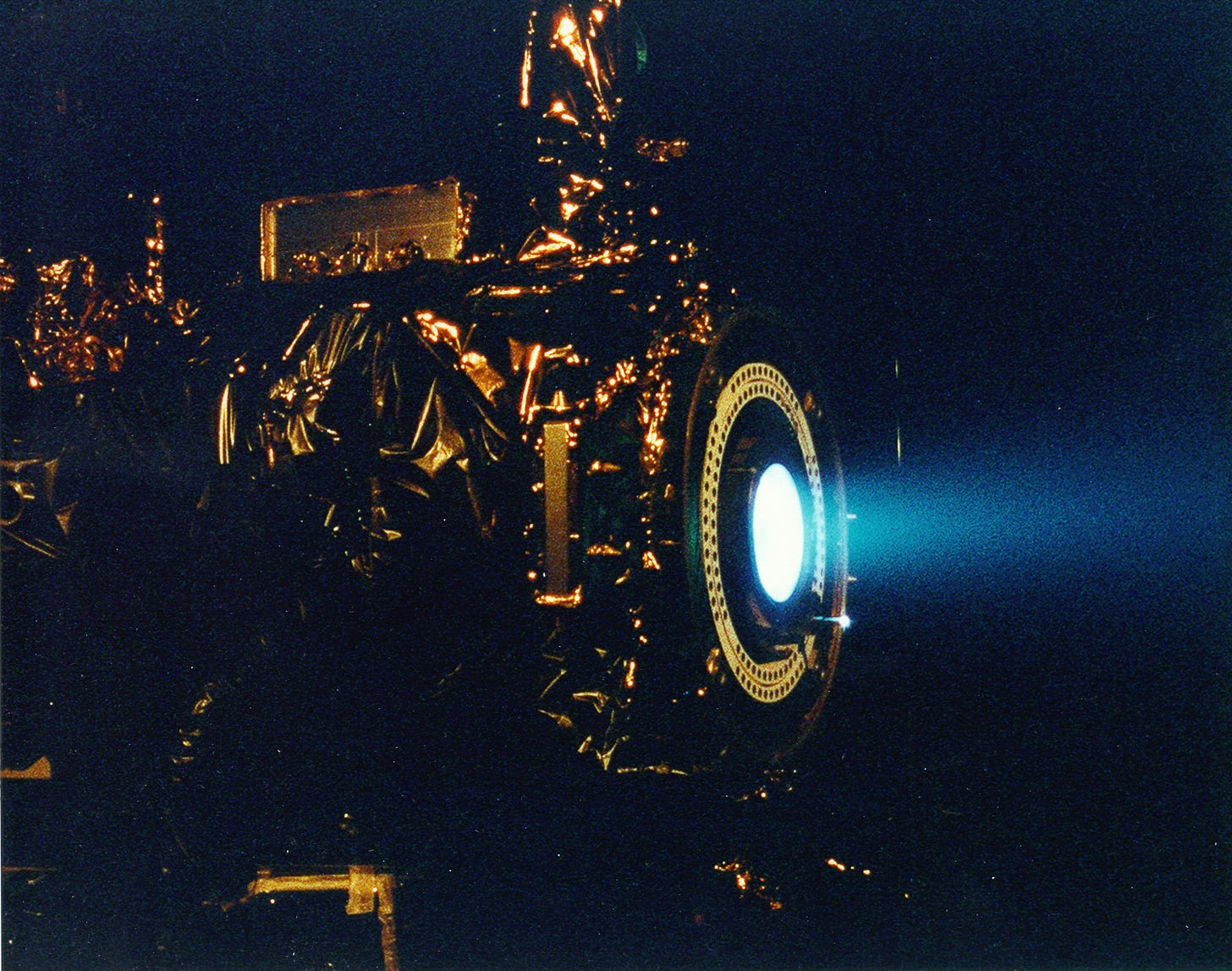

Ion, or plasma, thrusters use electricity to create charged particles and accelerate them out of the engine at extraordinary speeds. Exhaust velocities can range from 20,000 to 100,000 meters per second, roughly ten times higher than chemical engines, making them among the most efficient propulsion systems ever developed. The trade-off is thrust. Ion engines generate tiny fractions of what chemical engines can produce, far too little to lift a rocket from Earth. Yet in the frictionless vacuum of space, their steady push can be applied for months or years, gradually building up incredible velocities no chemical rocket could match.

Nuclear Propulsion

Nuclear thermal rockets replace combustion with a reactor. Hydrogen is heated to thousands of degrees inside the reactor core and expelled as exhaust, producing velocities of about 7,000–8,000 meters per second, roughly twice that of the best chemical rockets, while still delivering substantial thrust.

The United States tested such designs extensively in the 1960s under the NERVA program. The technology was nearly flight-ready before political concerns and budget cuts ended the program in 1973. Today, renewed interest in crewed Mars missions has revived discussion of nuclear rockets, including “bimodal” concepts that could provide both propulsion and onboard electrical power for long-duration spaceflights.

Light-based Propulsion

Light itself carries momentum. Though the force is tiny, over large surfaces and long periods it can move spacecraft. Solar sails, made of ultra-thin reflective sheets spanning kilometers, can harness sunlight to gradually accelerate across the solar system. Replace sunlight with powerful lasers, and in theory, small craft could be driven to a significant fraction of the speed of light.

Other laser concepts include heating onboard propellant directly, producing thrust without combustion. These ideas face enormous technical challenges, but they demonstrate how far propulsion concepts can expand once freed from the limits of chemical energy.

The Road Ahead

Chemical rockets remain the only way to leave Earth’s surface. Their ability to deliver colossal thrust makes them irreplaceable for launch. Yet once in orbit, the priorities shift and efficiency matters more than raw power. Electric thrusters already propel spacecraft across the solar system, nuclear systems are under renewed study for deep-space exploration, and light-based sails or lasers hint at propulsion methods that could one day carry probes to the nearby stars. The engines of spaceflight are as varied as the missions they serve, and together they drive humanity’s long effort to extend its reach beyond Earth.

References

College of Chemistry. n.d. H&S Section 7: Safe Handling of Cryogenic Liquids. UC Berkeley.

Dabanović, Andrija, Joel Martin, Stefan May, and Viola Wartemann. 2024. “Numerical Study on Post-Combustion Chamber Impact on Hybrid Rocket Performance.” Research Square (Research Square).

Friesen, Tara. 2024. NASA Next-Generation Solar Sail Boom Technology Ready for Launch. National Aeronautics and Space Administration. April 10.

Goebel, Dan M., and Ira Katz. 2008. Fundamentals of Electric Propulsion.

Gomes, Marc Faria. 2013. “Internal Ballistics Simulation of a Solid Propellant Rocket Motor.”

González, Carlos M. 2020. The Future of Nuclear Rockets for Space Travel. The American Society of Mechanical Engineers.

How Things Fly. Rocket Propulsion. National Air and Space Museum.

Leishman, Gordon. 2022. Introduction to Aerospace Flight Vehicles.

NASA. n.d. Rocket Propulsion. National Aeronautics and Space Administration. Accessed August 26, 2025.

NASA. n.d. Rocket Thrust Equation. National Aeronautics and Space Administration. Accessed August 25, 2025.

NASA. n.d. Space Nuclear Propulsion. National Aeronautics and Space Administration. Accessed August 29, 2025.

Newlands, Rick. 2023. “Hybrid Safety.” Aspirespace. Aspirespace.

Ray, Paul. 2002. “Independent Review of the Failure Modes of F-1 Engine and Propellants System.”

Sances, Dillon, Sathya Gangadharan, James Sudermann, and Brandon Marsell. 2010. “CFD Fuel Slosh Modeling of Fluid-Structure Interaction in Spacecraft Propellant Tanks with Diaphragms.” American Institute of Aeronautics and Astronautics.

Uhlenhake, Kyle E., Mateo Gomez, Diane N. Collard, Metin Örnek, and Steven F. Son. 2023. “Laser Ignition of Solid Propellants Using Energetic nAl-PVDF Optical Sensitizers.” Combustion and Flame 254 (May): 112848.

Walter, Ulrich. 2012. Astronautics: The Physics of Space Flight.